ALICE Technologies has developed an AI-driven platform that understands construction. This allows the exploration of millions of construction scenarios in just a few minutes, resulting in an average of 17% project duration reduction and a 14% labor cost reduction.

Construction scheduling is broken — just think of any project you know that is on time and on budget. The reasons for this are myriad, and the ability to plan and schedule a project lies near the heart of them all.

This article is the first of a series that dives into why planning and scheduling needs an update for the 21st century, and how Artificial Intelligence can play a role in helping solve its issues.

Before diving into the heart of this series, which is about the use of artificial intelligence (AI) for construction scheduling, we first need to understand why using AI is a good idea in the first place.

Why AI?

We begin by identifying the problems underpinning construction scheduling theory and practice. Two problems are highlighted: 1) the way in which project constraints are modeled and 2) the inability to evaluate various schedule sequences. Further discussion for each of these problems is included to highlight the value that is usually left unexplored in typical scheduling practices.

The second part of the series is used to explain basic concepts of artificial intelligence: what are the flavors of AI, what kinds of problems are they useful for solving, and which is best suited for the construction scheduling problem?

Finally, we discuss how AI is applied in our platform ALICE (ArtificiaL Intelligence Construction Engineering) and how it can benefit your organization.

Introduction: Construction Scheduling Theory and Practice

Much of the world’s $16 trillion construction industry is orchestrated using Gantt charts, first invented by Henry Gantt in the early 1900s, and most famously proven in the construction of the Hoover Dam in the 1930s. Underpinning most Gantt chart software today is the Precedence Diagramming Method, developed by John Fondahl in the 1960s. This method allows the identification of the Critical Path, the key theory underpinning construction scheduling since the mid 1950a, using the concept of task float. At ALICE, we take a slightly different, arguably more pragmatic definition of the critical path:

A task is on the critical path when a change to its duration is directly proportional to the resulting change in the overall project duration.

There are, however, theoretical short-comings of current techniques to identify critical paths. To illustrate these gaps in theory let’s take a look at a simple example of scheduling a parking garage.

Parking Garage Example

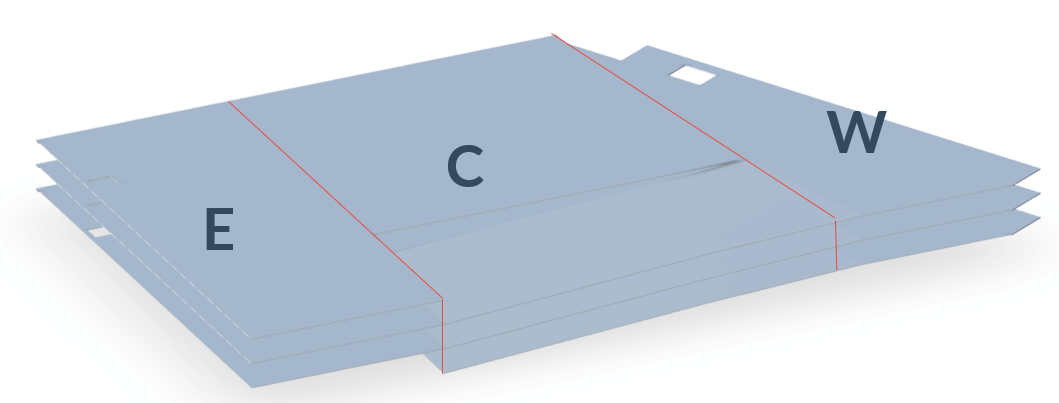

This example comes from one of the first projects run on the ALICE AI platform, it is a 7 story parking garage, that has been split into 3 sections: East, Center, and West.

The schedule is based on the following fragnet. It is used to model the construction of each section of the garage. The fragnet also repeats for each section on each floor:

Assuming a West -> Center -> East sequence, the ground floor schedule would look like this:

Can you identify any potential problems with this schedule? Do you notice that the Deck Form tasks overlap by one day? If we only hired one crew of each type, this schedule would have errors. Unfortunately, today’s tools are dumb to this error.

How do we make the tool more aware of this? The only tool available to schedulers is to add precedence constraints. The task of adding in additional precedence links would have to be manually completed for each instance of crew overlap, for each area, on each floor. This manual task becomes tedious quickly and is extremely error-prone.

What if we wanted to look at hiring two crews of each type? And how do we know if West -> Center -> East is actually the best sequence for this project? If we wanted to explore these different options, a new schedule would have to be manually created each time. Exhausting.

Despite being a simple example of construction scheduling, this parking garage project actually highlights three critical shortcomings of current schedule tools and theory.

First, the critical path method assumes infinite resources are available on a project. If CPM did not assume infinite resources, then the overlapping Deck Form activities would not occur.

Second, the only way to account for resource constraints in a schedule is using precedence links. In fact, the only way to model any type of constraint on a project schedule is using precedence links, this is a major limitation of scheduling tools.

Third, the use of precedence links locks in a sequence and current tools are unable to quickly look at simple changes to a project schedule. We highlight these shortcomings because they are actually theoretical limitations, which must be dealt with at a fundamental level.

In fact, Prof. Fondahl said this himself when he accepted the Peurifoy award in 1990,

…This brings up another related problem. Few of even those who claim to be “CPM experts” fully appreciate the fact that in a resource-restrained schedule the concept of float breaks down and quite often the concept of a critical path breaks down. Since almost all construction projects are resource-restrained, at least to some extent, this becomes a source of major problems.

The classic legal question in recent years, as well as the subject of numerous professional papers, is, “Who owns float time?” It is difficult to claim ownership of something that might not exist or that hasn’t been quantified properly. These are fundamental matters that after 30 years still don’t seem to be understood.

Thirty years later, these are problems that still exist today as we can see with this simple parking garage. Can you imagine what it like on larger, more complex projects?

Scheduling Columns

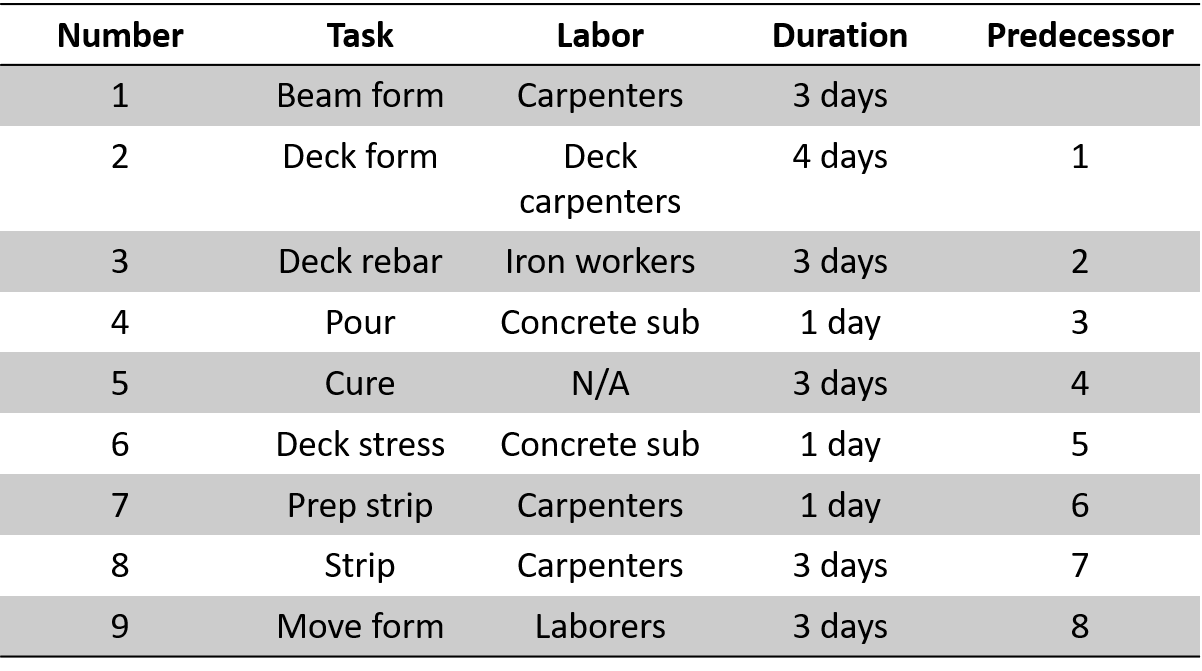

In this next example, we are comparing different levels of detail when scheduling. Let’s assume there are 12 columns on a floor that need to be built, and that we will create two scheduling approaches, one that schedules each column, one-by-one, and the other that builds 6 columns at once. This is akin to creating a task (or fragnet) by zone.

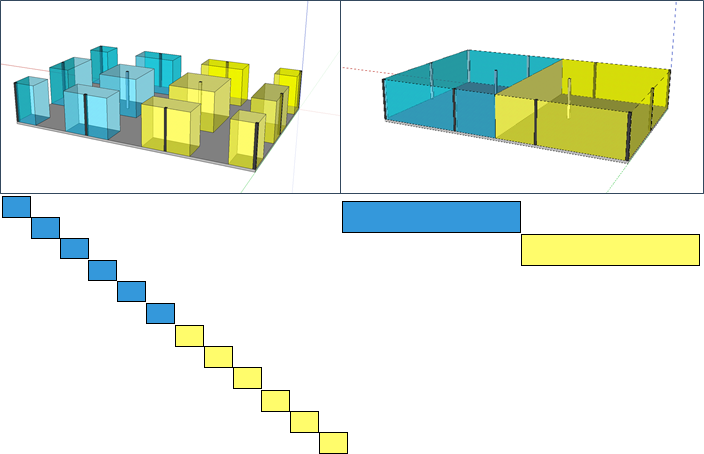

The schedules for each of these examples might look like they do in the image above. The next question is then, what happens when we add another crew? Think about this for a moment. By adding another resource, the durations should get shorter, in fact, they will get shorter by exactly half because we have doubled the number of crews from 1 to 2. What about the sequence?

The image above shows two different sequences, in both cases the duration decreases by half. In the first case, the two crews are used to work the column construction in parallel. In the second case, the crews work in the same colored zone and then move to the second zone. As you can imagine, the number of sequencing possibilities actually increase as the level of detail becomes more granular, as the example below showcases.

Tools for schedulers today, however, do not allow for sequence variation and exploration. Which begs the question, when you plan and schedule today, are you looking at the best sequence? Every change to the plan requires a new schedule to be made. With existing technology, this process is tedious and error-prone, which leads schedulers to work at more coarse levels of detail. And who can blame them? Unfortunately, this leaves value on the table unless you have a legion of schedulers to schedule at such a granular level.

Concluding Thoughts

Current tools limit the ability of planners and schedulers to explore sequence options. Consider briefly the parking garage example of phasing: East -> Center -> West. How many different sequence options are possible?

The answer is 3.2 million different possibilities! Some sequences force curing to occur over weekends, others maintain the flow as is, and others may balance resources better. What is astounding, is the number of sequences for what is seemingly a simple project.

Within each sequence, the critical path changes, float values change, and periods in which the schedule is logic constrained or resource restrained also change.

When we vary the sequence, we change when crews start on-site, when equipment arrives, and how long each needs to remain on the project. Often times on projects, those crews can be sitting idle, waiting for another crew to finish or maybe waiting for materials to arrive. What if you could look at and evaluate all the possible sequences at once? Sequences that reduce this idle time, that increase the efficiency of your resources on site. This translates directly to efficiency — dollars saved, value earned, and better project control.

Construction needs a new approach to scheduling to help develop and explore this world of possibilities. One that builds off the theories from the 20th Century, but also uses the latest techniques and advancements in computing that have marked life in the 21st Century.

References

Morkos, René, Martin A. Fischer, John C. Kunz, and Michael Lepech. 2014. Operational efficiency frontier: visualizing, manipulating, and navigating the construction scheduling state space with precedence, discrete, and disjunctive constraints. http://purl.stanford.edu/qz016sf9089