Over the past four years, 4D Construction Management has become a big part of my life. In particular, I became really passionate about construction planning and scheduling. Hospitals, airports, water treatment plants, power plants, bridges, etc. needed to be built and having the opportunity to help make that happen faster and more efficiently made me happy.

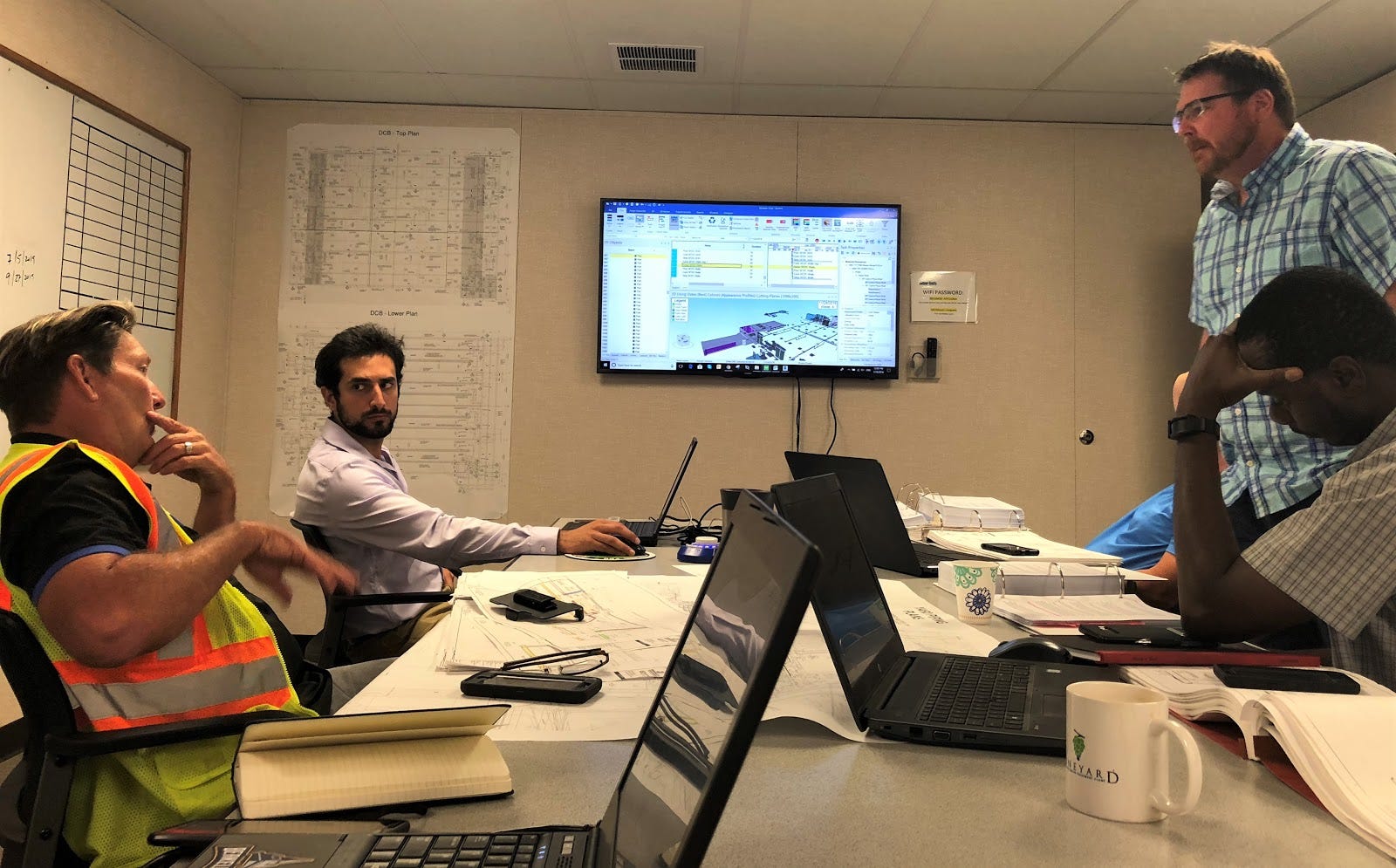

My time was almost equally split between conducting seminars all over the globe, working with software development teams to integrate user feedback, and providing 4D planning + scheduling consulting services. For the last one, my job would be to sit down with different superintendents, display the BIM model up on a large screen, and ask all the necessary questions in order to be able to build a reliable CPM schedule. That is a schedule that can be used by the different trade teams to figure out when, where, and what to work on at any given day so that their work fits nicely with the overall sequence and the project as a whole is finished in the shortest possible duration.

Here I am (second guy from the left) building a construction schedule for a wastewater treatment plant with the superintendents

Here I am (second guy from the left) building a construction schedule for a wastewater treatment plant with the superintendents

The pain of scheduling the manual way

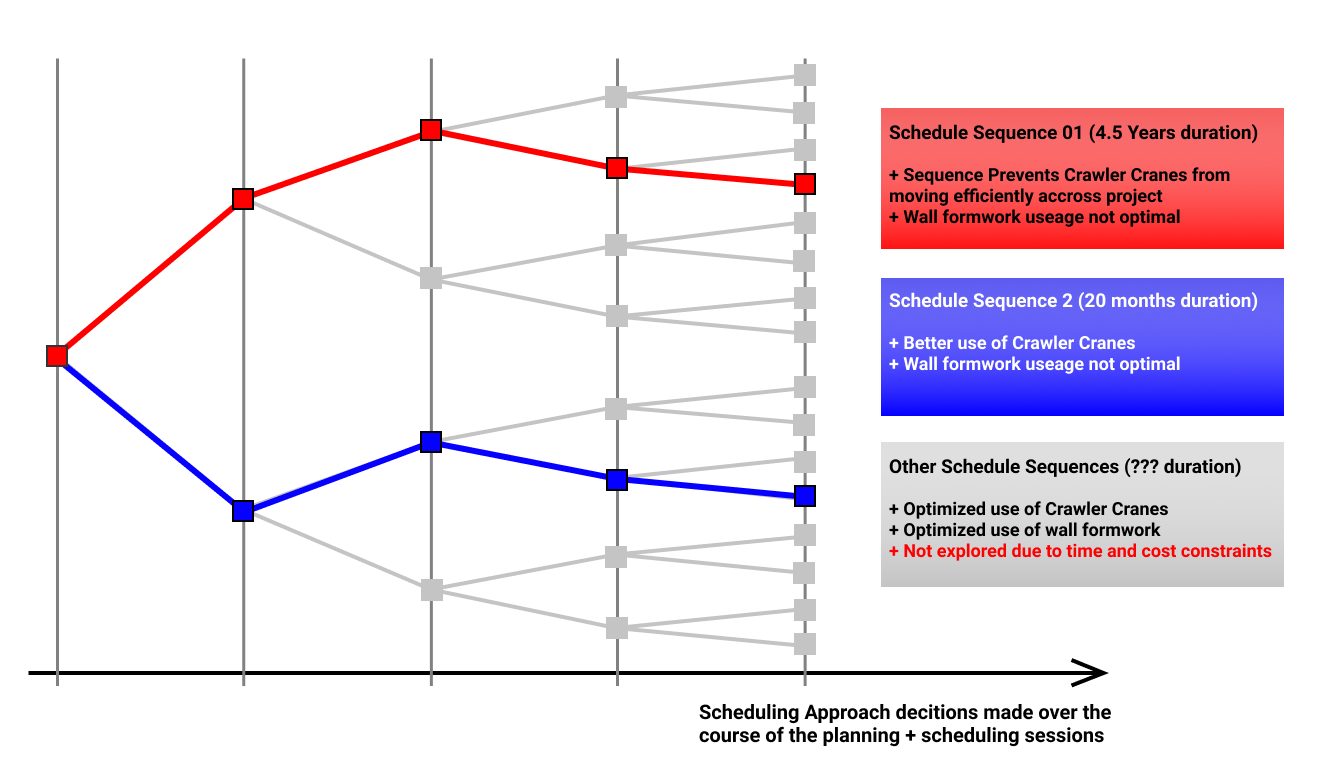

If you’re a planner or scheduler, you’ll know that this can be a really tedious effort. Over the course of a few weeks, you have to manually type in the information and logic sequence for thousands of activities only to end up with a single construction plan that may or may not be satisfactory. For example, in the case of the project pictured above, a wastewater treatment plant I worked on before joining ALICE, the first iteration produced a 4.5 years schedule duration for a scope that was originally estimated (during the bidding phase) to only need 18 months of construction. We then had to spend almost as much time for the second iteration to re-sequence the flow of work and shorten that duration to about 20 months (and hope that a 2 months acceleration would happen during construction via the power of magic).

The work was a bit frustrating because even though we knew how each component was going to be built, as well as all the hard constraints for the project, modeling a single scenario with a single crew mix would take several days.

In short, the below figure summarizes our process.

With every sequence decision made during those planning sessions, we would be ruling out potentially hundreds of schedule approaches that may have been worth investigating. In addition, there wasn’t any real way for us to figure out the best possible schedule given our constraints (resource availability, number of cranes on site, space utilization, etc.). We had to just assume a scenario and then evaluate it.

When you think about it, this is a pretty inefficient process. If you have the BIM Model, know the steps to build each type of component, are able to input the hard constraints, AND it’s 2019, then why can’t software do the rest for you?

Enter ALICE

ALICE takes in the BIM Model, uses a mesh analyzer to figure out the support relationships (they can also be modified by the user), and then applies your construction “recipes” for every possible construction sequence while taking into account physical constraints, as well as labor, equipment, and space availability. Behind the scenes, ALICE will generate millions of 4D resource and cost loaded schedules and then display the best 5–10 sequences for any desired crew and equipment mix. For example, you can quickly investigate what adding a crane or having crews work overtime affects your schedule. What I was impressed with the most here, is that this is NOT the simple “more crews -> smaller task duration -> faster construction if critical path is affected”. ALICE will actually take into account your new resource pool and use the AI engine to evaluate all the possible new schedules and present you with the best ones. You can then set one of these new schedules as your baseline and use it to manage your project.

This makes ALICE a game changer. Changing the fundamental way planning is done:

-

Construction planning and scheduling are now parametric.

-

Planners and Schedulers are now empowered to effortlessly create 4D schedules.

-

The created schedules are all resource and cost loaded.

-

True resource/equipment sensitivity/saturation analyses can now be done in minutes.

-

Schedule reviews now consist of reviewing the recipes, constraints, and resource pool rather than thousands of line items with start and finish dates.

-

The ability to easily re-sequence ongoing projects should any changes and delays occur.

Check out our website at www.alicetechnologies.com and reach out to us for a custom demo of our AI-driven planning and scheduling platform.